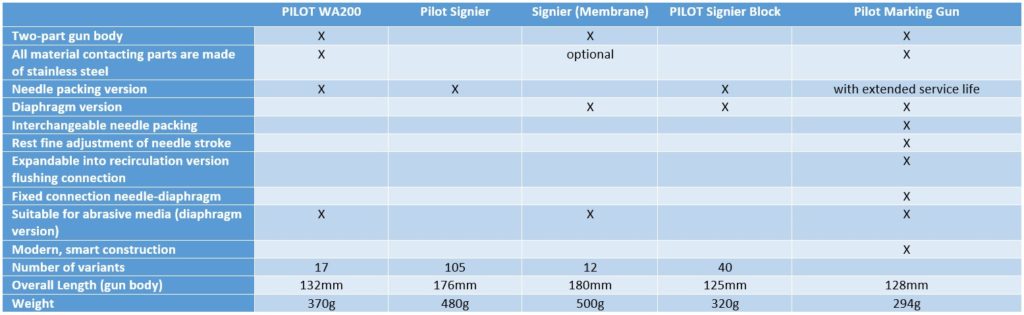

The Walther Pilot Signier Series will be obsolete as of January 31st, 2020, replaced by the feature dense, non-surface damaging GA 9010. Here are all the best reasons to make the switch.

The Pilot 9010 marking’s primary uses are marking dots and lines, alphanumeric marking and painting with sharp edges. Most of the applications for these uses fall under four categories:

- Quality check markings

- Differences between quality and uses on similar or identical looking parts

- Cut, bending and folding guidelines

- Assembly prosses color coding

Being 30% shorter and 20% lighter, the GA 9010 is more compact and lightweight than its predecessor. Other improvements in marking quality come from stainless steel parts and a smooth cap-nut, allowing for easy cleanup.

The GA 9010 comes bundled with a precisely adjustable/interchangeable needle and interchangeable diaphragm.

The essential equipment needed to operate the GA 9010 are:

- Pressurized material cups: MDG 1,2,3,4 and or dual diaphragm pump, MBP 2812

- Pneumatics cabinet

- Solenoid valve, 3/2-way

- Hose set

- Fittings and connectors

Additional options, like spray gun holders, agitators and fill level gauges, are also available for guns in the GA 9010 line.

Every part of the GA 9010 has been re-engineered to separate itself from other automatic spray guns.

First, the 1/8” material inlet connection on the top of the gun features a plated brass M5-F connection with a stainless steel option available. This inlet allows for material hose connections to be mounted easier, making use quicker and safer. To users, that means easy integration into systems and fewer headaches during maintenance. Four different material inlet connection locations are available on the gun, allowing users to run hoses from the top, bottom, left or right.

Internally, the GA 9010 features stainless steel material passages, including the fluid passage, nozzle and needle. By making the gun internals stainless steel, parts will last longer, cleaning will be easier, and the risk of gun damage will be lower.

Externally, the GA 9010 is faster to clean, crafted with a black anodized aluminum air body.

All this adds up to less time spent cleaning and less money spent replacing parts.

The all-new flushing connection comes standard on GA 9010 guns, reducing cleaning time to 10 seconds. Quicker flushing is especially useful after a long break or when using fast-curing material.

On the bottom of the gun, Walther Pilot has added three mounting holes, so replacing GA 9010s is quick and easy, avoiding time spent matching gun alignments.

Another improvement has been made to the back of the gun, with its material volume adjustment. This new adjusting knob has 0.5mm travel per revolution, giving the gun a material flow rate with extremely precise regulation.

Individually, these improvements save time, money and make the gun easier to use. Together, they make up a must-have spray gun for any work that demands high accuracy and a high-quality automatic spray gun.

Buy now at https://store.cetinc.com/